Välinge Innovation’s click furniture technology, first presented in 2014, makes furniture assembly easier and quicker then ever before. And without visible holes for fasteners, bolts etc., it opens up entirely new opportunities for furniture design.

The key feature of Välinge’s click furniture technology is the plastic displaceable tongue that locks boards or panels when pushed together. One of the resulting benefits is the speed and ease of which furniture can be assembled. Neither tools nor spare parts such as fasteners and bolts are required.

For consumers, the click furniture technology means that there is no longer any need to read complex instruction manuals or to spend time trying to find the right spare parts. Furniture arrives in flat packages and is ready for fast, easy and tool-less assembly. As an example, a standard cabinet can thereby be assembled in seconds instead of minutes.

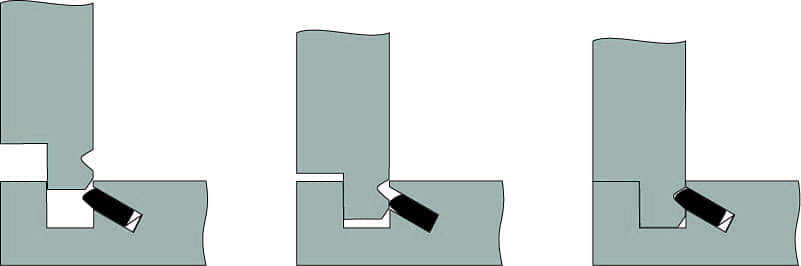

Schematics of furniture installation: Panels are locked when pushed together.

The furniture panels are produced with the locking element (plastic tongues) pre-mounted at the factory. Using standard 4.5 or 5 axis CNC-machines, producers have a short production start-up time and can within short start shipping packages to its customers. As there is no need for gluing or pressing, this new technology also enables factory assembly to become significantly more effective.

The 5G-T technology uses the same plastic tongues as the locking solution for flooring. As the function is provided by the tongue, the technology is suitable for all materials that can be machined to a profile such as particle board, HDF, MDF, CDF, plywood, solid wood, plastic, WPC, HPL and more. The strength in the tongue combined with the long connection surface makes the 5G-T connection extremely stable, in turn resulting in very robust furniture.

Välinge has developed the profiles needed for complete furniture, all with respect to their functionality. One example is the corner profile. This profile has been developed to have maximum strength along the corner edges, as these are the most sensitive parts on the furniture. Another example is the back piece profile that secures a 90-degree angle and stabilizes the whole construction. Backsides are otherwise typically nailed and require all corners to be carefully measured in order to secure a 90-degree angle.

Profile examples: Back profile (left) and corner profile (right)

Since Välinge Innovation introduced its 5G fold down technology for flooring at the end of 2004, the technology has been used worldwide by the company’s licensees in the production of more than 900 000,000 square meters of flooring area. Based on this technology, Välinge introduced its click furniture technology in 2014 and a number of furniture manufacturers have already realized the opportunities. The first products from Välinge licensees will be available in the market during 2015.

Välinge will demonstrate its technology at the upcoming show interzum in Cologne on May 5-8.